Call us now: +86 371 5512-9198

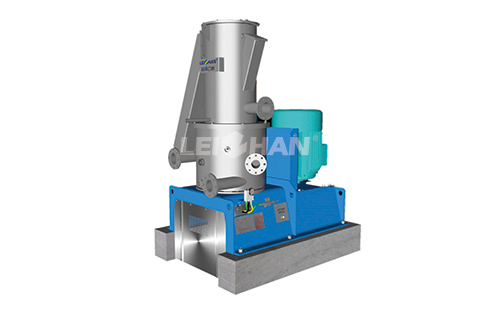

TD Series Tailing Pulp Pressure Screen of Coarse Screen

Application&Features

1. Mainly used for the deflaking of the tailing pulp and the separation of light impurities at the end of the waste paper pulp screening system;

2. Continuous operation, large capacity;

3. Adapted to high concentrations, close to 3%;

4. The reject discharging concentration is close to 30%;

5. Working under closed condition, the environment is clean;

6. The fiber loss rate is low.

TD Main Specification

|

Type |

TD1 | TD2 |

|

Production capacity(t/d) |

60-80 |

80-100 |

|

Concentration of Input Pulp(%) |

<3 |

|

|

Concentration of Reject(%) |

≈30 |

|

|

MAX.working pressure(Mpa) |

0.15 |

|

| Motor Power(KW) | 75 |

90 |