Call us now: +86 371 5512-9198

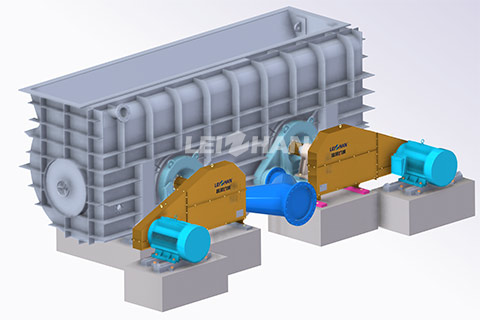

SZS Series Broken Pulper

Application&Features

1. Mainly used for broken paper treatment from press section, calender, paper reel section, etc;

2. Optimized rotor shape for higher turbulence at the lowest consumption;

3. High pumping efficiency greatly increases the friction between the fibers – not only relying on mechanical forces between rotor and screen plate for pulp disintegration.

Main Specification

|

Model |

SZS1 | SZS2 |

SZS3 |

|

Rotor Dia.(mm) |

750 | 1000 |

1300 |

|

Width of the chest(mm) |

2500-5000 |

3500-6000 |

4500-8000 |

|

Pulp consistency(%) |

3-5 |

||

|

Screen hole size(mm) |

10-24 |

||

| Motor power(KW) | 45-160 | 90-355 |

200-630 |